|

TEST DATA AND INFORMATION

|

|

COOLER AIR TRACK OIL TEMP WATER

KIT TEMP TEMP TEMP DROP GAUGE

944 TURBO OUT 82 F 98 F 257 F -55 F 1/2 mark

944 TURBO IN 82 F 98 F 202 F Just < 1/2 mark

944 OUT 81 F 108 F 258 F - 52 F Just > 3/4 mark

944 IN 81 F 108 F 206 F Just > 1/2 mark

Testing was done at Heartland Park, Topeka, a 2.5 mile, 16 turn course, ( 944Turbo), August 1996, N/A May 1997 These temperature drop readings have been confirmed by costumers with simlar insutrumentation.

|

944 Turbo Notes:

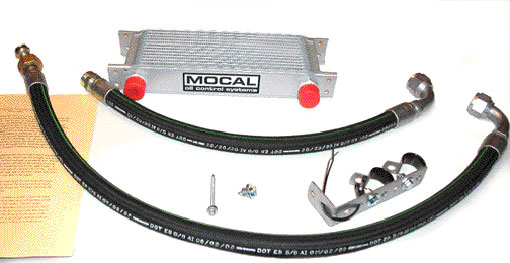

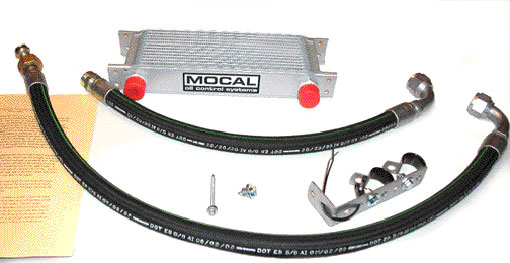

The car used was an `86 Turbo and would be raced in “F” class in PCA and many driver education weekends with two drivers. Before our first season, I knew that this car was going to get a workout with two drivers in the hot Kansas summer. My goal was to get additional oil cooling without adding heat to the radiator air flow, restricting radiator and brake air flow or butchering the car. I spent many hours figuring out how to position all the parts, tracking down the oddball metric adapters, experimenting with hose lengths and routings and getting the airflow needed. This 13 row Mocal cooler installation has been on the car since 1995 and has worked perfectly. We are always the coolest Turbo at the track, seldom getting past the middle mark on the water temp gauge. It is installed in series with the OEM cooler and retains the factory oil temperature thermostat so the proper temperatures are maintained for warm up and protection of the coolers in cold weather. The hoses are slightly larger than the factory hoses. The Turbo installation allows the cooler to get good air flow with the driving light installed but it can get even more with the light removed and modifications done as outlined in the kit instructions. As with the 944 kit, the light can be easily removed at the track for maximum airflow and installed for street driving or left out for a dedicated track car. The temperature sender was installed in line after the factory cooler to measure the temperature just before it is returned the vital engine parts. For the test without the cooler, the lines were configured back to the stock configuration.

Turbo Comments:

In stock configuration, 257 F was measured after the oil had been through the factory cooler. If you assume that the factory cooler is only half as efficient as my cooler, (which provided a 55 F drop), you could easily assume that the oil temperature leaving the engine could be well over 270 F. That is TOO HOT. And it was only an 82 F day. At these temps, the film strength of motor oil begins to be reduced rapidly. Also note that we had about a ½ mark drop in the water temperature and we also noted almost a full bar higher oil pressure at full rpm on the long straight with my kit installed.

944 Notes:

The 944 is an `83 model that I purchased new and have autocrossed and used at driver education events regularly. The radiator/air conditioner has always had a screen and is very clean.

The cooler was mounted behind the left driving light with the light removed and one 3X5” inch hole cut in the driving light bucket. Air flow to the cooler was through this hole and the gap below the bumper. In the kit are instructions and parts to allow the removal of the entire back of the light bucket providing a 3X5 inch hole for air flow directly into the cooler and the capability of quick removal and installation of the light between track and street driving.

Oil flow in the 944 begins with pick up in the oil pan, to the oil pump, to the water/oil heat exchanger below the oil filter, to the outside part of the oil filter and returns to the engine through the center post of the oil filter. This kit uses a Mocal sandwich plate with a temperature thermostat that mounts between the oil filter and the engine and sends the oil to a 13 row Mocal cooler. The temperature sender was installed in line after the cooler to measure the temperature just before it is supplied to the vital engine parts. For the test without the cooler, the sender adapter took the place of the cooler which was completely out of the system.

Comments:

What amazed me was the temperature of the oil being supplied to engine without the cooler. After the oil has been through the water/oil heat exchanger it is still at 258 degrees. That is very hot, ask any 911 guy. I would be scared to find out the oil temperature leaving the engine before it went to heat exchanger. As you can see in the chart, not only did the cooler knock 52 degrees off the oil temperature, but with the water and oil “mixing”, the cooled oil put less strain on the coolant system resulting in a full quarter mark drop on the water temperature gauge. Also note that it was not as hot as it could have been in Kansas in August. I shudder at the thought of what the oil temperature has been on those many days at the track when it was 100 or more.

General comments:

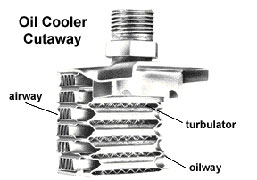

The Mocal cooler is very efficient and designed for racing to get the most cooling in the smallest area with the least weight. It is designed and built in England where most of the F1, Cart and Prototype cars are designed. Mocal coolers are used widely in these series as well as NASCAR. Some attempts at additional oil cooling use OEM coolers, designed for mass production, that mount in front of the radiator. This generally results in higher water temps (much like running with the A/C on), more weight and is much more involved to install. When water temps go up, it becomes more likely that the engine management system will have to back off on boost and retard timing to avoid detonation. When it does that, power output is reduced. (I consider this a bad thing) My kit has no impact on radiator or brake cooling performance. It has no negative impact on any system in the car.

Radiator type coolers, as used in this kit, do a much better job of removing foam and aeration from the oil than a condenser or trombone type cooler. Foamy oil at excessively high temperatures is likely a major factor in the dreaded #2 bearing failures. Reducing oil temps is one of the easiest ways to lengthen engine life.

The 13-row cooler provides at least 468 sq. in of surface area to airflow. (2 in. deep rows, top and bottom, 9 in. wide, 13 rows)

My goal during design and development was always to keep it simple and make it work. I think you will find that these kits have met that goal.

Images:

Credits: Terry Morris, KISS Engineering

| Related Articles |

> Window Express Kit Installation

> AC Delete

> Accusump Installation

> Adjustable Ride Height Kit - Paragon

> Alternator Replacement

> Brakes, front - 924S, 944, 944S

> Brey-Krause Strut Brace Installation - 944

> Camber Plate Installation (Paragon)

> Clock/Bulb Replacement, digital, Late 944 and 968

> Clutch Replacement - Part One

> Clutch Replacement - Part Two

> Clutch Slave Bleeder Valve Remote

> Control Arm Bushing Upgrade - Weltmeister

> Control Arm, Front - Info

> Coolant Flush

> DME Chip Installation

> Dash Replacement

> Engine Identification

> Engine Production

> Fuel Level Sender

> KLA Strut Brace Installation - 924S, 944, 968

> Koni Strut Conversion - 8641-1414S for late 944, 968

> Motor Mount Replacement

> Odometer Gear Replacement - late 944

> Oil Pressure Relief Valve

> Oil Pressure Sending Unit Replacement

> Rear Ride Height Adjustment

> Porsche Chronology

> Rear Spring Rates vs. Effective Rates

> Rear Wheel Bearing Diagnosis

> Rear Wheel Bearing Replacement - 924, early 944

> Rear Wheel Bearing Replacement - late 944, 968

> Ride Height Measurement

> Rod Bearing Replacement

> Shift Lever Rebuild

> Short Shift Kit

> Throttle Position Sensor

> Sway Bars - Info

> Torque Tube Rebuild

> Torsion Bar Replacement

> Transaxle Fluid - Info

> Transaxle Fluid Change

> Rear Sway Bar Installation

> Transaxle Replacement

> Heater Clip

> Window Regulator Replacement

> Seat Back Brace Installation Instructions

> KLA Strut Brace Installation - 968/944 S2/944 S

|

|